Kolkata, West Bengal

Industrial Chemicals

Water is often called the universal solvent – a property that can cause unwanted side effects for industrial applications. Water can dissolve many substances, including gases like oxygen and carbon dioxide. As a result, water can cause corrosion of metals used in cooling systems.

As water concentrates in cooling systems, dissolved ions may exceed the solubility of some minerals and form scale. The life-giving properties of water can also encourage bacterial growth that can foul system surfaces. These problems require proper treatment and control to maintain the value of a cooling water system to the process it serves. Cooling water systems are an integral part of process operations in many industries. For continuous plant productivity, these systems require proper chemical treatment and preventive maintenance.

SOME IMPORTANT PROPERTIES IN COOLING WATER CHEMISTRY :

- CORROSION : Manufacturing of common metals used in cooling systems, such as mild steel, involves removing oxygen from the natural ore. Cooling water systems are an ideal environment for the reversion of the metal to the original oxide state. This reversion process is called corrosion.

- SCALE : Hardness such as bicarbonate, sulphate salt of calcium, magnesium and silicates are relatively insoluble in water and deposit on heat exchange surfaces of cooling water systems forming an insulating layer, decreasing its heat exchange efficiency.

- BIOLOGICAL CONTAMINATION : Cooling water systems provide an ideal environment for microbial organisms to grow, multiply, and cause deposit problems in heat exchange equipment. Microbial growth can strongly influence corrosion, fouling, and scale formation, if not controlled properly.

Metal Surface Treatment Chemicals

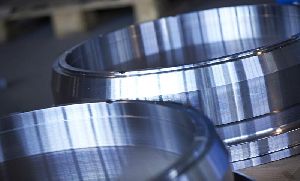

All the metals have a tendency to return to the form as oxides that they naturally exist. Hence, corrosion is a natural phenomenon. The purpose of the treatment is to provide protection against corrosion. Further, microcrystalline textures of metal surfaces are so very smooth that they normally support minimum adhesion to the metal surfaces. Treatment has another purpose that is to improve paint adhesion. There are various types of PHOSPHATING for different types of metals. The process even further varies with various applications of the same metal.

Galvanizing is a process of imparting a sacrificial zinc coating on the iron or steel surface, thereby protecting the surface from atmosphere. Method of application differs according to the need and availability of measures.

The most popular galvanizing method is Hot Dip Galvanizing which is adaptable to almost all types of fabricated and non fabricated items. Flux type Continuous Galvanizing Line is such a kind where iron or steel strips are degreased, pickled and fluxed for surface preparation before dipping into the molten zinc.

Major Steps :

ALKALINE CLEANING - Removing oil, grease and soil from steel surface is crucial, otherwise dissolution of iron oxide / scale by pickling will be retarded.

ACID PICKLING - Ferrous metals have a surface coating of metallic oxide and / or scale which must be removed before zinc coating can be applied successfully. Pickling involves immersing the work in an acid to dissolve the scale or oxide film.

FLUXING - Liquid flux is recommended for continuous galvanizing line (C.G.L). It is used directly without any dilution. It has the ability to keep the sheets free from oxides by removing the rust blush prior to dip in the zinc bath. It also improves the zinc – iron adhesion in the galvanizing process.

PASSIVATION - Chromate conversion coating chemical is applied on galvanized iron and zinc –aluminum surfaces. It imparts excellent corrosion resistive coating that protects the underlying surface from weathering.

In case of nonox lines no fluxing is required. Further, depending on the sheet condition, acid pickling stage may also be omitted.